In today’s diverse technological landscape, the complexity and cost associated with developing and manufacturing electronic products are ever-increasing. This is where contract electronics manufacturing (CEM) comes into play, supporting and developing your production. Whether you’re a startup looking to bring your tech idea to life or an established company seeking to optimise your manufacturing process, understanding the nuances of CEM can be a game-changer.

Prism Electronics Manufacturing Limited has long been recognised for its ability to manage complex electronics manufacturing requirements from initial prototype to full production. The company has built a solid reputation for delivering reliable manufacturing solutions tailored to industries where performance, precision, and long-term support matter most.

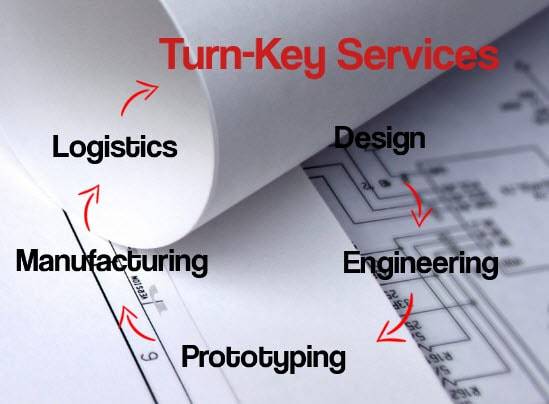

The company’s core offerings include advanced surface mount technology for densely populated printed circuit boards, through-hole assembly for mechanically demanding components, and complete box build services that integrate electronics with enclosures, wiring, and mechanical systems. Prism also supports electro-mechanical assembly, enabling the delivery of fully integrated and tested systems ready for deployment.

Testing and inspection are central to Prism’s approach. The company performs a full suite of quality checks, including functional testing and in-circuit testing, and ensures every product meets the rigorous requirements of IPC-A-610 Class 3 standards. This attention to detail allows Prism to maintain the highest levels of reliability, particularly for customers operating in regulated or safety-critical environments.

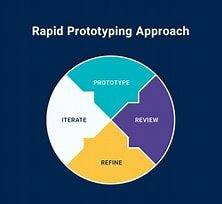

In addition to manufacturing, Prism offers close engineering collaboration with clients during the early stages of product development. While not a design house, the company contributes valuable expertise in design for manufacturability, helping customers optimise product layouts, reduce costs, and improve long-term performance. Prism also provides prototyping, legacy product support, and complex rework services, including modifications and component updates for products in mid- or late-stage lifecycles.

Prism has consistently demonstrated its commitment to best-in-class manufacturing practices. The company has operated under ISO 9001:2015 certification for quality management and ISO 14001:2015 for environmental management, ensuring strong internal processes and a sustainable approach to operations. Assemblies are built to strict industry standards, including J-STD-001 and IPC-A-610 Class 3, confirming Prism’s capability to deliver to the highest levels of quality and reliability.

With end-to-end assembly capabilities, expert staff, and a rigorous approach to quality, Prism Electronics Manufacturing has served as a valuable extension of its customers business.