PRISM CAPABILITIES

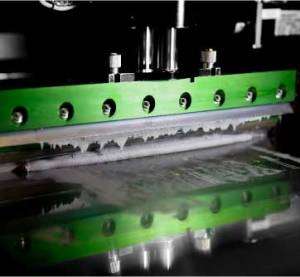

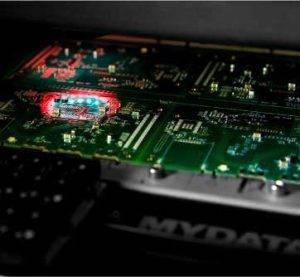

Our surface mount assembly capability is built upon our robust New Product Introduction (NPI) process employed for every new product. We perform an automated inspection using a ‘HawkEye’ enabled DEK screen printer to ensure process repeatability during the paste printing operation. During pick & place we present components using tape & reel, JEDEC trays and waffle-packs. Our attention to process control continues through Automatic Optical Inspections (AOI) at both pre-flow and post-flow stages. Solder reflow is performed utilising either a multi-zone convection oven or through a vapour phase reflow (VPR) system.

Surface Mount Assembly (SMA) describes the mounting of electronic components to the surface of a printed circuit board (PCB) in preference to inserting components through holes within the board as is the case with ‘conventional‘ plated through-hole PTH assembly. SMA was originally developed to drive down manufacturing costs and facilitate PCB miniaturisation through increased component density within a given PCB area. The technology continues to promote increasingly complex electronic assemblies leading to ever smaller form factors with the added reliability of process automation.

CONTACT OUR SALES TEAM

We only use the personal information entered below to contact you regarding the specific products and services offered by Prism Electronics Ltd. We will either contact you directly or through our nominated marketing partner(s). Your right to privacy is respected and you can request removal from our contact list at any time by completing the form and selecting the appropriate checkbox for removal. Here are links to our Privacy Policy and Terms and Conditions.

Follow Us On Social Media For Capability Updates and News!

QUALITY AND VALUE

Prism Electronics Ltd are committed to;

- Delivering on time and in full following a ‘right first time’ methodology.

- Communicate in a timely and effective manner with our customers and suppliers.

- Strive for zero defects as the only acceptable target through continual improvement.

- Ensuring we operate our business in a professional and ethical manner at all times.