PRISM CAPABILITIES

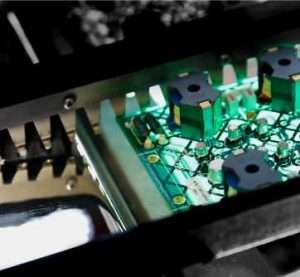

Prism has been providing Conventional PTH assembly for over 30 years and has the capability to provide RoHS and non-RoHS assembly. All our operators are trained to IPC-A-610 Class 3 inspection and are regularly assessed by our in-house IPC qualified training staff. Multiple soldering workstations provide a large capacity for hand solder assembly. Prism has two CMS-400 Blundell Wave soldering systems installed, each dedicated to either a RoHS or non-RoHS process. We employ both manual and AOI inspections post assembly. We also hold a vast array of supporting equipment and tooling to provide repeatable component preparation and finishing.

Conventional assembly (also referred to as PTH or Plated Through-Hole) is the more traditional method of populating Printed Circuit Boards (PCBs). The component leads are placed through a pre-drilled hole on the bare printed circuit board. The components can be soldered into place either by hand soldering (with a soldering iron), or by the use of a wave flow soldering system. Flow soldering is the preferred method for medium to large production volumes and is used (where possible), to reduce process times and therefore assembly costs.

While this method of assembly has reduced over recent years due to the emergence and necessity of SMT, it can still often be considered as the preferred method for products used within harsh environments or components . The intrinsic mechanical strength of through-hole assembly provides additional support to the component in high stress applications where shock, vibration and high temperature conditions exist.

CONTACT OUR SALES TEAM

We only use the personal information entered below to contact you regarding the specific products and services offered by Prism Electronics Manufacturing Ltd. We will either contact you directly or through our nominated marketing partner(s). Your right to privacy is respected and you can request removal from our contact list at any time by completing the form and selecting the appropriate checkbox for removal. Here are links to our Privacy Policy and Terms and Conditions.

sales@prism-electronics.com

Follow Us On Social Media For Capability Updates and News!

QUALITY AND VALUE

Prism Electronics Manufacturing Ltd are committed to;

- Delivering on time and in full following a ‘right first time’ methodology.

- Communicate in a timely and effective manner with our customers and suppliers.

- Strive for zero defects as the only acceptable target through continual improvement.

- Ensuring we operate our business in a professional and ethical manner at all times.

COMPANY INFORMATION