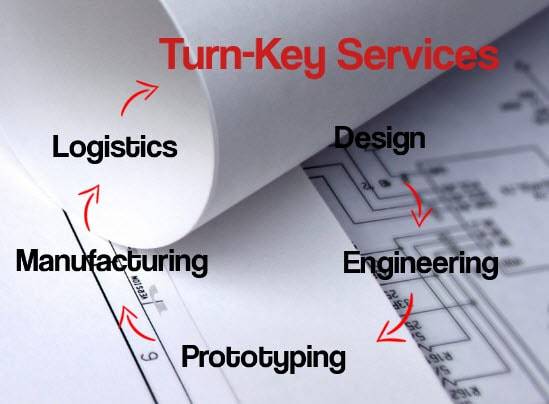

What is Full Turnkey Manufacturing?

Full turnkey manufacturing is a comprehensive solution, offering a streamlined approach that encompasses everything from design to delivery.

At its core, full turnkey manufacturing providers take on the responsibility of managing every aspect of the manufacturing process, including:

- Design and Engineering: It all begins with a concept or an idea. Full turnkey manufacturers often offer design and engineering services to help clients refine their concepts, optimise designs for manufacturing, and ensure product feasibility.

- Procurement of Materials: Sourcing quality materials at competitive prices can be a significant challenge for businesses. Full turnkey manufacturers leverage their networks and purchasing power to procure necessary components and materials efficiently.

- Prototyping and Testing: Before mass production, prototypes are crucial for validating designs and functionalities. Full turnkey manufacturers typically offer prototyping services, allowing clients to test and make changes on their products before moving to full-scale production.

- Production and Assembly: This is the heart of full turnkey manufacturing. Once designs are finalised and materials are procured, production lines are set up to manufacture the products according to specifications. Assembly, testing, and quality control processes are integrated seamlessly into the production workflow.

- Logistics and Fulfilment: From packaging to shipping, full turnkey manufacturers handle the logistics of getting the finished products to their destinations. This includes warehousing, inventory management, and coordinating shipments to ensure timely delivery.

Benefits of Full Turnkey Manufacturing:

- Simplified Supply Chain Management: By consolidating all manufacturing activities with a single provider, businesses can streamline their supply chains, reducing complications and potential bottlenecks.

- Cost Savings: Full turnkey manufacturing can often result in cost savings due to economies of scale, efficient procurement practices, and reduced overhead costs associated with managing multiple vendors.

- Time Efficiency: With all stages of production under one roof, the time from initial concept to market launch is significantly reduced. This agility can be a competitive advantage in fast-paced industries.

- Quality Assurance: Centralised production allows for tighter control over quality at every stage of the manufacturing process. Full turnkey manufacturers typically have rigorous quality assurance protocols in place to ensure that products meet or exceed industry standards.

- Flexibility and Scalability: Whether producing small batches for niche markets or scaling up for mass production, full turnkey manufacturing offers the flexibility to adapt to varying production volumes and market demands.

In Conclusion:

Full turnkey manufacturing offers a universal approach to product development and production, providing businesses with a one-stop solution to bring their ideas to life. By integrating design, engineering, production, and logistics into a seamless workflow, full turnkey manufacturers empower businesses to focus on innovation and growth. However, careful evaluation of providers, clear communication, and strategic planning are essential to unlocking the full potential of this manufacturing model.

For more information about how Prism Electronics can help with all your turnkey manufacturing needs please visit our website: prism-electronics.com