Accelerating Success: The Power of Fast Turnaround in Contract Electronics Manufacturing

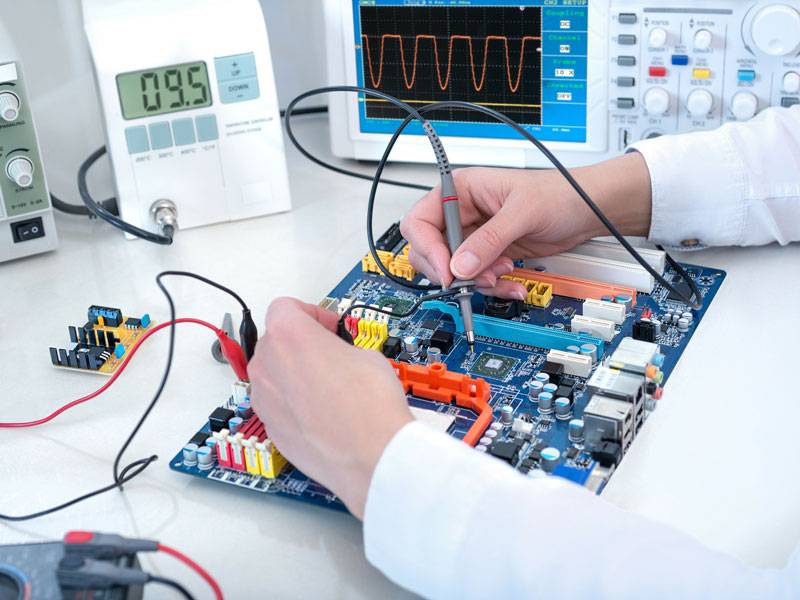

In the ever-evolving landscape of electronics manufacturing, speed is of the essence. The ability to swiftly transform concepts into tangible products is not just a competitive advantage but often a prerequisite for success. In this fast-paced industry, contract electronics manufacturing plays a pivotal role, offering companies the opportunity to leverage specialised expertise and resources without bearing the burden of in-house production.

The Need for Speed

Time-to-market can make or break a product. From consumer electronics to industrial machinery, every sector demands rapid innovation and delivery. This urgency is fuelled by diverse customer requirements, evolving technological standards, and intense market competition. Consequently, companies face immense pressure to streamline their production processes and accelerate the journey from design to distribution.

Embracing Contract Electronics Manufacturing

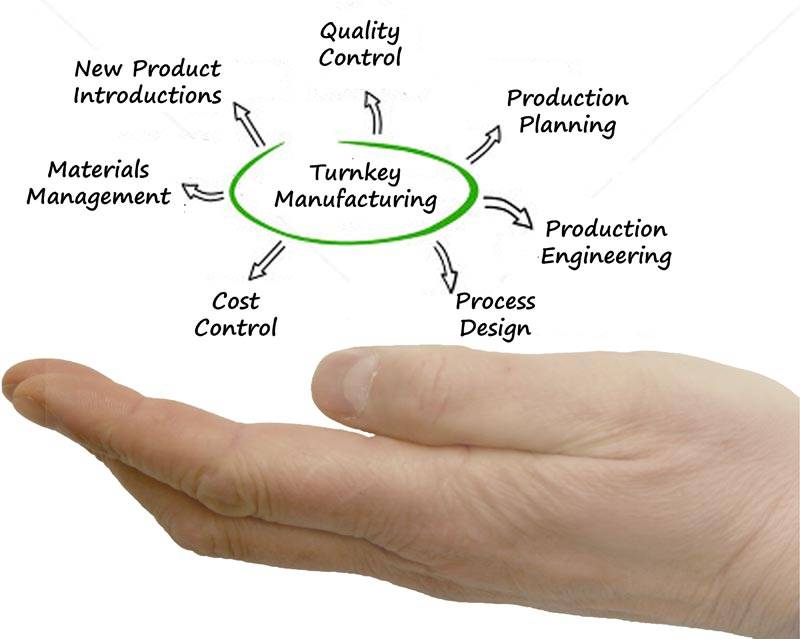

Enter contract electronics manufacturing (CEM), a strategic outsourcing solution that enables companies to focus on their core competencies while entrusting manufacturing tasks to specialised partners. CEM providers bring a wealth of experience, infrastructure, and scalability to the table, offering full turnkey manufacturing services encompassing design, prototyping, assembly, testing, and logistics. By partnering with CEM firms, businesses gain access to advanced technologies, industry insights, and cost efficiencies, thereby enhancing their agility and competitiveness.

Key Benefits of Fast Turnaround:

- Agility: Fast turnaround enables companies to adapt quickly to market dynamics, facilitating rapid iterations, customisation, and scalability.

- Reduced Time-to-Market: By compressing production timelines, fast turnaround expedites product launches, allowing businesses to capitalise on emerging trends and consumer preferences.

- Cost Efficiency: Despite the emphasis on speed, fast turnaround solutions optimise resource utilisation and minimise waste, ensuring that accelerated timelines do not compromise cost-effectiveness.

- Enhanced Collaboration: Collaborative partnerships between clients and CEM providers are reinforced through transparent communication, iterative feedback loops, and rapid prototyping iterations.

Driving Factors Behind Fast Turnaround:

- Advanced Technologies: Leveraging state-of-the-art equipment, automation, and digital tools, CEM firms optimise manufacturing processes for speed and precision.

- Full Turnkey Manufacturing: Seamless integration of design, manufacturing, and logistics functions enables CEM providers to streamline workflows and minimise lead times.

- Supply Chain Optimisation: Strategic sourcing, vendor partnerships, and inventory management strategies are optimised to ensure timely procurement of components and materials.

- Process Innovation: Continuous improvement initiatives, lean methodologies, and agile practices foster a culture of innovation and efficiency within manufacturing facilities.

Conclusion

In the dynamic realm of contract electronics manufacturing, speed is paramount. By embracing CEM services companies can transform their manufacturing processes, elevate their competitive edge, and improve their supply chain. As the pace of technological innovation accelerates, the ability to respond swiftly and decisively will continue to be a cornerstone of success in the contract electronics manufacturing industry.

For more information about how Prism Electronics can help with all your fast turnaround manufacturing needs please visit our website: www.prism-electronics.com