Entering the field of contract electronics manufacturing can be a complex journey. With the UK market being highly competitive and technology constantly evolving, it’s crucial to have a clear strategy and the right mindset to establish your presence. In this no-nonsense guide, we’ll provide you with specific steps to help you not only break into the contract electronics manufacturing market but also thrive within it.

Know Your Target Audience

Before you jump into the contract electronics manufacturing sector, immerse yourself in thorough market research. Identify your niche within the industry, whether it’s producing medical devices, automotive electronics, or consumer gadgets. Understand the unique needs and preferences of your target audience, as this knowledge will be the foundation of your success.

Create a Unique Value Proposition

Differentiation is the key in contract electronics manufacturing. Your company must offer something distinctive and valuable, whether it’s outstanding quality, efficient production processes, or innovative supply chain solutions. Your value proposition should resonate with potential customers and make your manufacturing services exceptional.

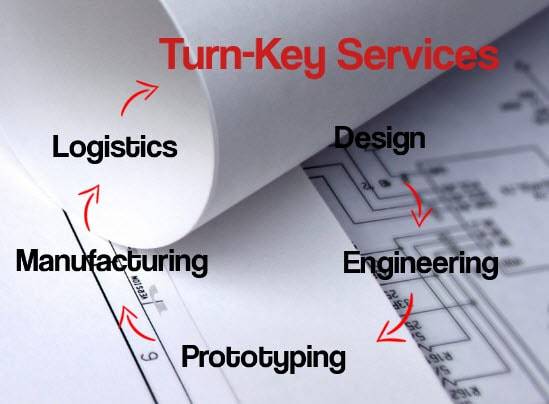

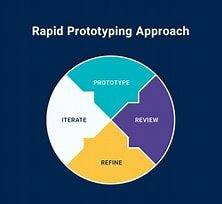

Develop Prototypes and Prove Your Expertise

Invest in creating prototypes or sample products to showcase your manufacturing capabilities, even is this means outsourcing the initial design and build. Customers want assurance that you can deliver on your promises, and a physical example of your work can go a long way in building trust. Additionally, having a successful track record of manufacturing similar products can demonstrate your expertise to customers.

Protect Your Intellectual Property

In the contract electronics manufacturing world, intellectual property is often a sensitive issue. Ensure that you have proper agreements in place to protect your customers’ designs and data while also safeguarding your proprietary manufacturing processes.

Forge Strong Supplier Partnerships

The quality of your contract electronics manufacturing largely depends on your suppliers and partners. Establish reliable partnerships with component and material suppliers known for their quality and reliability. Negotiate favourable terms, and maintain open communication to address any supply chain challenges promptly. Consider outsourcing product that requires additional technical support.

Establish an Online Presence

In today’s digital age, having a strong online presence is indispensable. Develop a professional website showcasing your capabilities, certifications, and successful projects. Utilise digital marketing, including content creation and social media engagement, to connect with potential clients and build brand recognition.

Prioritise Customer Support

Exceptional customer service is vital for success in contract electronics manufacturing. Provide responsive and knowledgeable customer responses to address queries, solve manufacturing challenges, and ensure a smooth production process. Happy customers are more likely to become loyal partners and refer your services to others.

Embrace Change

The contract electronics manufacturing industry is continually evolving, with new technologies, materials, and production methods emerging regularly. Stay informed about industry trends, client preferences, and technological advancements. Be prepared to adapt your manufacturing processes and strategies to remain competitive and relevant in the market.