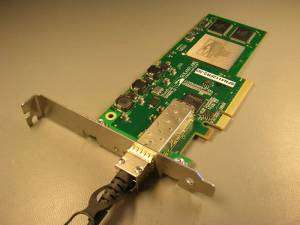

Prism has secured a contract to provide highly complex PCBs for the development of 10 Gigabit high speed Ethernet cards.

Solarflare Communications, a leading provider of high-performance Ethernet semiconductor solutions, has selected Prism to supply PCBs for the engineering evaluation of its new 10 Gigabit reference design cards that are being produced at its development centre in Cambridge.

Prism Electronics is providing highly complex PCBs to help develop Solarflare’s 10 Gigabit Ethernet solutions which will enable next-generation applications such as cloud computing, Web 2.0, and server virtualisation.

Solarflare’s 10 Gigabit Ethernet solutions enable next-generation applications such as cloud computing, streaming media, Web 2.0, server virtualisation and network convergence. Solarflare is working with key industry partners and customers to ensure interoperability and drive a complete 10GBASE-T ecosystem.

“Our solutions are designed for use in applications within banks, financial institutions, government bodies and utilities where high-performance networking and product reliability is essential,” said Derek Roberts, VP Hardware Architecture at Solarflare.

“We opted for Prism to supply PCBs because of its attention to detail and excellent overall build quality. Prism’s engineers are also extremely willing to work with us to understand our requirements, which differ from the norm. We need engineering build scales and a fast turnaround – sometimes at short notice – for development purposes and Prism is able to adapt its production to suit our volume needs.”

David Dickin, business development director at Prism, said: “The PCBs Prism produces for Solarflare are complex and require many small 0402 components and ball grid arrays (BGA). Availability of the materials is variable and Solarflare can require a build turnaround of under three days at short notice. Prism is able to provide dynamic production scheduling to meet these requirements.”

Derek Roberts said: “It is difficult to manage this level of development production and service at a distance. That is why it is important to have a local partner like Prism which understands our requirements and can successfully overcome the design complexity and timescale challenges that we set.”

David Dickin added: “We are delighted to be working with Solarflare on its high speed Ethernet solutions.

“During product development, the periods of honing design and preparing for manufacture are critical times. It often needs careful, meticulous dialogue with specialists in these areas to ensure that products are fully optimised for production, test and reliability. It is easier to maintain this level of support with a reliable local partner.”