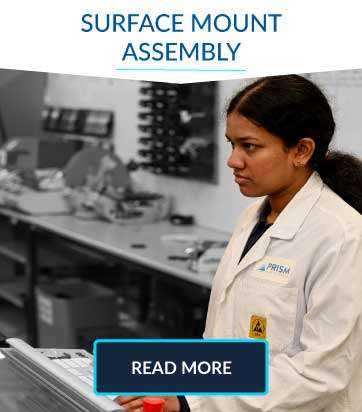

OUR CAPABILITIES

Proven expertise in PCB, Box-build and Electro-Mechanical Assembly

ABOUT PRISM ELECTRONICS

Established in 1991 we are an award-winning contract electronics manufacturing services provider. We are ISO9001:2015 and ISO14001:2015 certified supporting numerous market sectors with their electronics requirements. We are privately owned by FC Group Invest, committed to providing our customers with the highest levels of service.

PRISM ELECTRONICS LTD NEWS

Latest news, customer and industry articles related to the electronics manufacturing sector

New Partnerships: Working Together to Develop Innovative Technology

When Huntingdon-based company Paragraf looked to develop their Multi Sensor Test Unit (MiST), they needed a manufacturing partner who could provide the expertise to get the product from design to production. Paragraf’s patented 2D graphene deposition technique allows their graphene Hall sensors (GHS) to deliver high-quality, ultra-high-resolution magnetic field measurements across a wide spectrum of operating conditions [...]

Prism’s Paul Promoted to Quality Manager

Staff at St Ives (Cambridgeshire) based contract electronics manufacturing services provider Prism Electronics (www.prism-electronics.com) are celebrating the promotion of one of the companies longest serving members of staff. Paul joined the company in 1992 as a conventional assembly operator. The company was at their old premises and when the company moved, Paul went with them. “Prism has always been a friendly and pl [...]

The Role of Solder Reflow Machines in Contract Electronics Manufacturing

Introduction In the world of contract electronics manufacturing, efficiency, precision, and reliability are paramount. Manufacturers constantly strive to meet the demanding requirements of their customers, ensuring that the electronic products they produce are of the highest quality. One critical aspect of this process is soldering. While there has been a growing shift towards lead-free soldering in recent years due to [...]

Growing With Prism Electronics

Gardasoft Vision Limited, a small but ambitious company with innovative ideas in the field of LED lighting control for machine vision systems, approached leading contract electronics manufacturer (CEM) Prism Limited in 2005 for help with the manufacture of printed circuit board assemblies for its products. Eighteen years later, Gardasoft has grown to become a world leader in LED lighting controllers and very high bright [...]

QUALITY AND VALUE

Prism Electronics Ltd are committed to;

- Delivering on time and in full following a ‘right first time’ methodology.

- Communicate in a timely and effective manner with our customers and suppliers.

- Strive for zero defects as the only acceptable target through continual improvement.

- Ensuring we operate our business in a professional and ethical manner at all times.